Who this guide is for

This guide is for UK teams planning Christmas gift boxes — whether you’re a maker or creator, in buying, merchandising, operations, fulfilment, or simply the person everyone hands the “Christmas packaging problem” to every year.

Expect a practical guide, minimum order quantity tactics that won’t leave you drowning in cartons, and reorder triggers that actually work during Q4.

Need inspiration?

Browse our Christmas gift boxes

Build your range in three phases

To keep things calm (or at least, calm-ish) during peak, design your festive range in three simple phases: Early → Core → Last-Minute.

Start small, expand once demand proves itself, then simplify when December hits and everyone’s moving at the speed of a checkout queue on Christmas Eve.

1. Early Phase (late September, early October)

- Goal: Be first to market, gather reviews, and get photography live while competitors are still defrosting.

- Colours: Two neutrals (e.g. black and kraft), plus one accent (e.g. red or green).

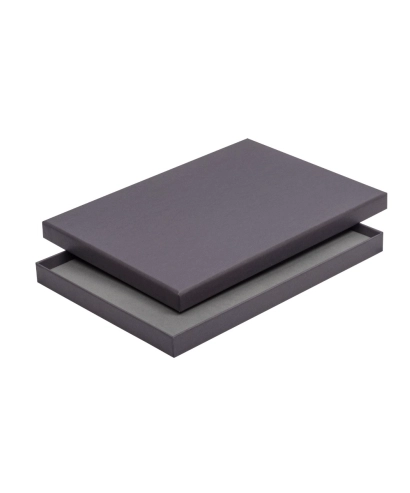

- SKUs: 6–10 core Christmas gift boxes with lids across small/large nesting sets.

- Packs: Smaller cartons or mixed cases to hit MOQ without overstocking.

- Add-ons: Matching ribbon, tissue, and reusable tags for a premium finish.

2. Core Phase (October–November)

- Goal: Keep bestsellers in stock and scale with confidence.

- Colours: Retain early colours and introduce one metallic accent (gold or soft silver).

- SKUs: Add 6–12 more gift boxes (extra sizes + one hero finish).

- Bundles: Pre-built gift sets (box + tissue + ribbon) to lift AOV and speed up decisions.

- Reordering: Top up using real sell-through data — no guesswork.

3. Last-Minute Phase (December)

- Goal: Fast picks and guaranteed stock.

- Colours: Reduce to your top two performers.

- SKUs: Fastest sizes only; switch to in-stock or local supply.

- Upgrades: Foiled tags and metallic tissue — low risk, high impact.

- Substitutes: Pre-approved alternatives so swaps are smooth if something goes OOS.

For timing guidance and buffers, see:

Plan festive packaging timelines with confidence

Your festive SKU ladder

A simple, expandable structure you can steal, adapt, and drop straight into your spreadsheets.

| Step | When | What to add | Approx. count | MOQ tactic |

|---|---|---|---|---|

| Core start | Late Sept | S/M/L nesting boxes in 2 neutrals + 1 accent | 6–10 SKUs | Mixed cartons by size; split colours |

| Prove & add | Mid Oct | Add XL / smaller sizes + 1 metallic finish | +4–6 SKUs | Top-ups only once ≥30% weekly sell-through |

| Peak build | Late Oct–Nov | Gift-ready bundles | +3–5 kits | Use bundles to move slower colours |

| Simplify | Early Dec | Retire slow colours; keep top two + hero | -2–4 SKUs | Convert remaining stock into bundles |

Demand signals & reorder points (Q4-friendly maths)

Nothing complicated — just a few light formulas to keep you in control.

Reorder point (ROP)

ROP = (Average weekly sales × (lead time in weeks + 1 buffer week)) + safety stock

Safety stock

- 1–2 weeks for standard stock

- 2–3 weeks if freight or finishes may be delayed

Trigger rule

If you sell through ≥30% of on-hand stock in a week, place a top-up.

Cut-off rule

After the first week of December, stop custom reorders and switch to stock-only.

Example

You sell 40 medium black boxes per week. Lead time = 1.5 weeks. Buffer = 1 week. Safety stock = 40 units.

ROP = 40 × (1.5 + 1) + 40 ≈ 140 units

MOQ-smart buying (hit minimums without wasting stock)

- Mix-and-match cartons: split colours within a size.

- Nesting logic: shared bases or lids reduce component count.

- Pack-size ladder: half-cartons early; full cartons once proven.

- Cross-season utility: non-dated designs that work beyond December.

Colour & finish consistency

- Lock brand colours with Pantone C/U and approved CMYK builds.

- Keep physical drawdowns as your master reference.

- Avoid introducing new shades in December.

- Reorder using identical specs for consistent lots.

Kits & bundles that lift AOV (and simplify picking)

- Starter kit: S/M/L box set + 10 sheets tissue + 5m ribbon

- Premium kit: Soft-touch hero box + metallic tissue + foiled tag

- Eco kit: Kraft boxes + paper raffia + recycled tissue

Publish these as ready-to-ship SKUs so last-minute buyers can click and go.

Switch-ins & risk cover (when something goes OOS)

- Pre-approve alternates by size and colour (e.g. black ↔ deep navy).

- Photograph alternates early for instant product-page swaps.

- Keep ribbon and tissue within the same palette.

Storage & staging

- Phase-zoned shelving: Early, Core, Last-Minute clearly labelled.

- Pre-kitting bundles ahead of peak.

- Pick-face layout: heavy items waist height; hero colours eye level.

- QC rhythm: check on arrival + weekly through Nov–Dec.

Sustainability guardrails

- Avoid year-specific prints.

- Choose recyclable boards and minimal laminates.

- Use bundles to clear slower colours.

- Right-size outers to reduce emissions.

Playbooks & tools

- Range planner: SKU ladder, colourways, reorder triggers.

- Open-to-buy checklist: phase budgets, MOQs, buffers.

- Sample kits ordered early for sizing and photography.

Check out our blog on sampling that avoids surprises under studio lights.

Need inspiration?

Browse our Christmas gift boxes